|

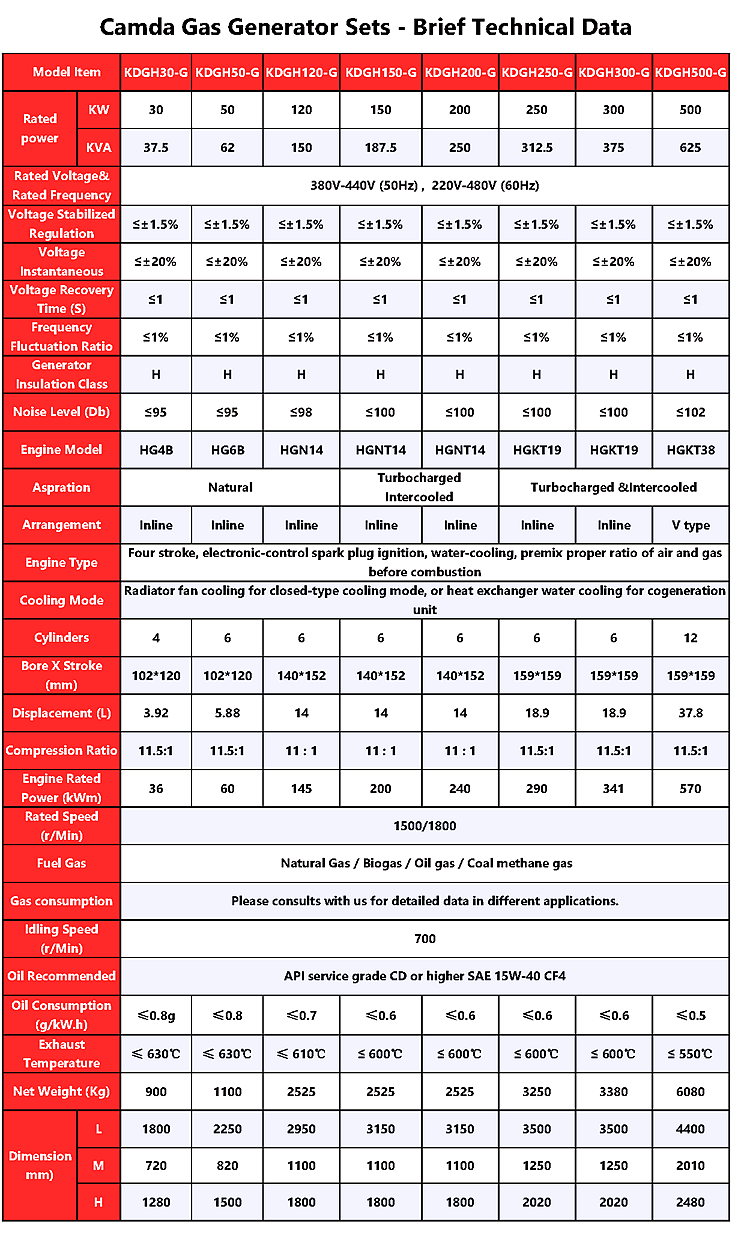

Fuel gas type: Natural gas, biogas, landfill gas, oil field gas Genset acceptable working conditions: Ambient temperature: 0°C ~ +40°C Relative humidity: Lower than 90% (20°C) Altitude: Lower than 500m, if more than 500m, every increase 100m, the power decrrease 1% Genset power output rated under the conditions: Atmospheric Pressure: 100kPa, Ambient Temp: 20°C, Relative Humidity: 30%

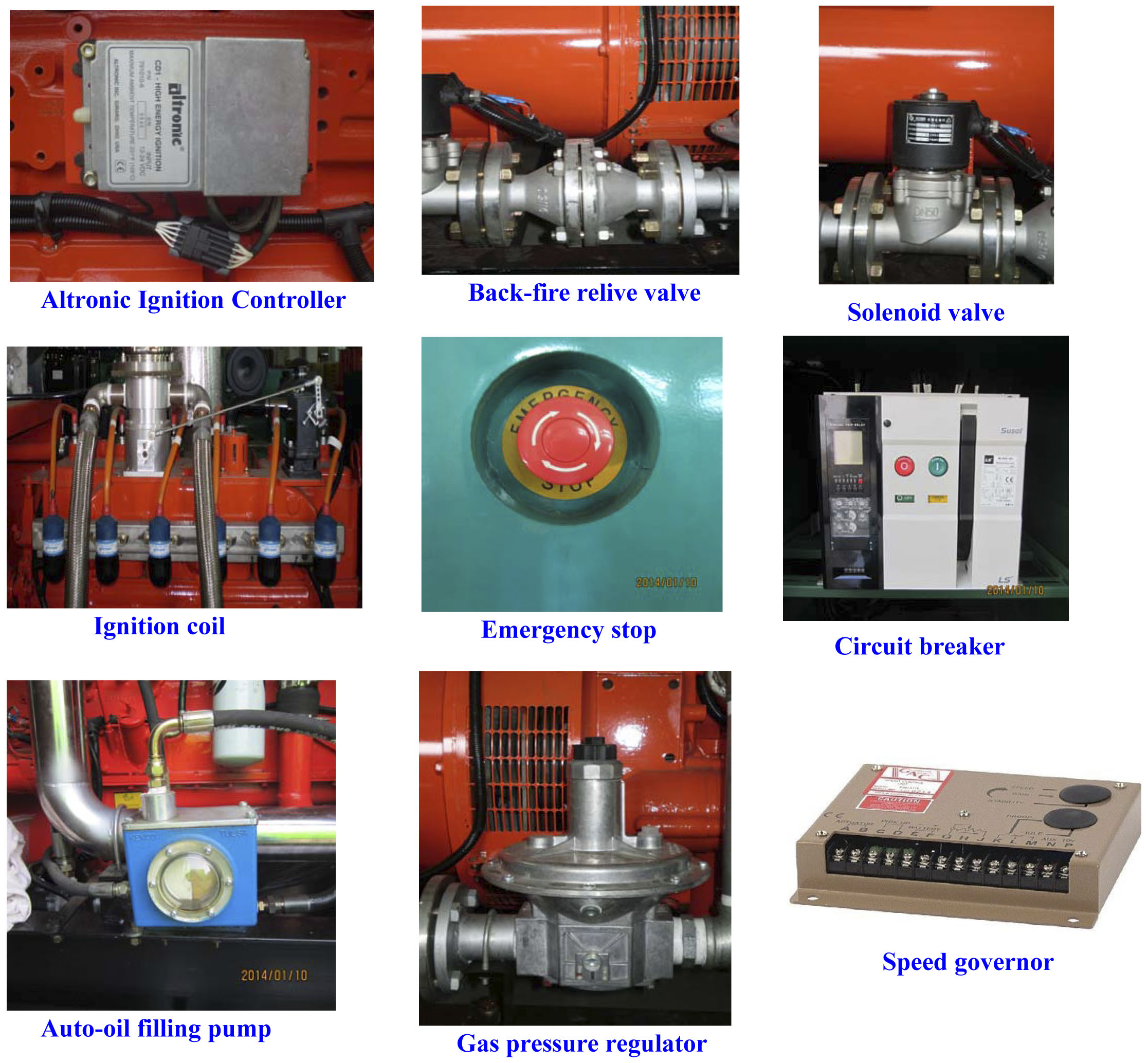

Standard Scope of Supply: 1.Brand new gas engine, 90% parts from Cummins engine body such as crank shaft, cam shaft, piston, cylinder head; 2.Brand new brushless alternator Rating: 3 phases 4 lines. 400/230V, 50 HZ , 1500rpm, 0.8PF, IP22-23, Insulation class H; 3.Radiator for 40°C/50°C ambient temperature; 4.Ignition system adopted USA ALTRONIC; 5.Emergency stop mounted; 6.Battery,Battery cable and Battery charger; 7.Standard tool box; 8.Standard Accessory for installation (include bellows,silencer,flange,asbestos pad,Anti-rust water,screw ) 9.Gas Train include Regulator valve,Electromagnetic Valve, Fire arrestor,Ball Valve

|

Easy accesible and easy servicable using international recognized brands

Specially designed Air/Gas mixer for working with fluctating heatvalues in the gas

Compact CHP units with Heat exchangers and Pumps

High Quality durable components used

this is a typical containerized unit for medium size gensets

|

NOTES

|